FEATURE:

* Mechanical PCB fixing+ visual positioning Mark points,high precision;

* Fastjob-changing,fast speed, and various components handling.

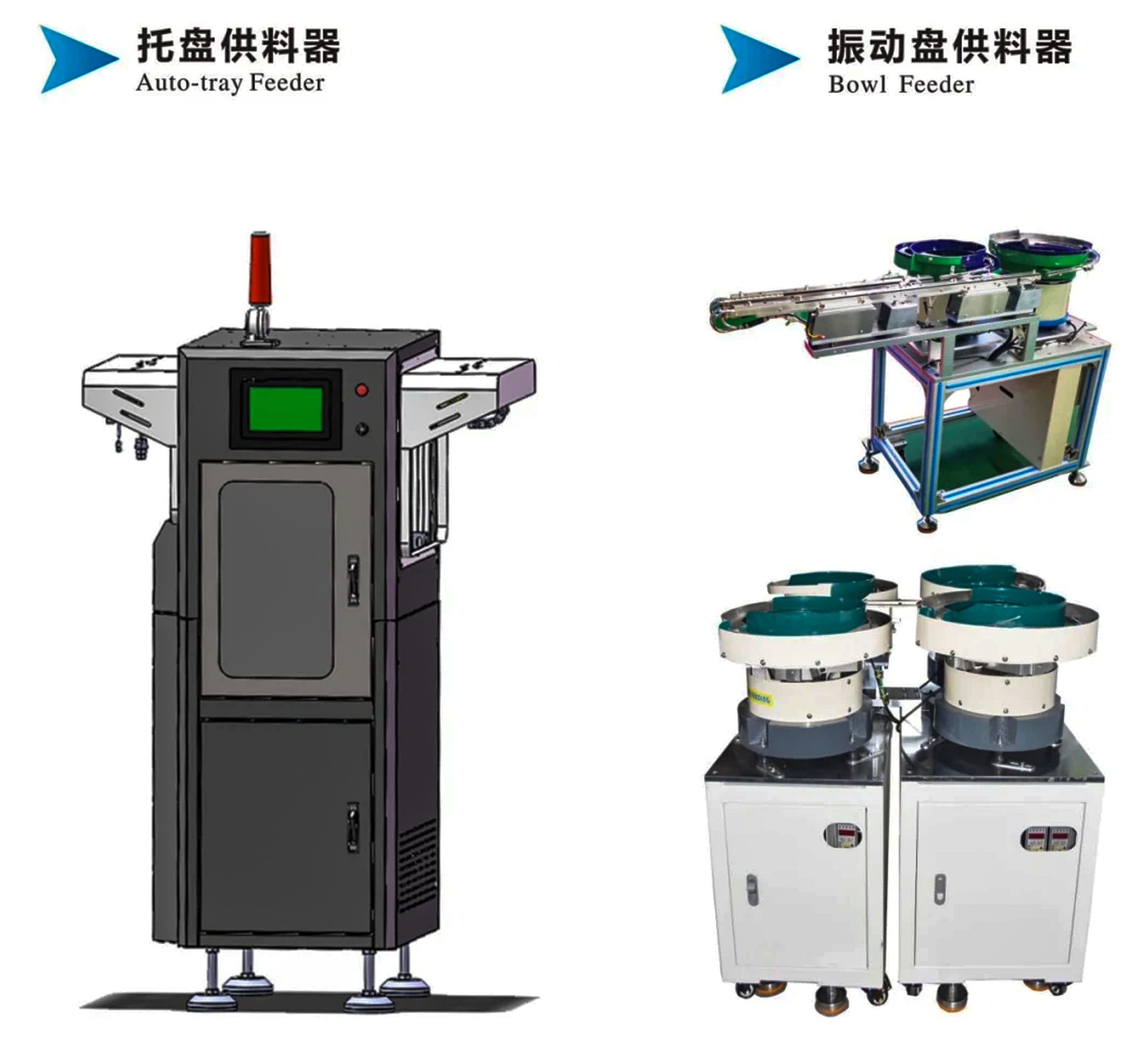

* Flexible and independent Feeder is versatile and easy to replace.

* It can automatically supply 4 kinds of packaging components for bulk,tape,tube and pallet.

* According to different customers,we can formulate different solutions to satisfy different customers’requirements.

1. The odd-shaped electronic component inserting machine completes the automation of the traditional inserting through visual mark points,robots. and automatic feeding mechanisms. The high insertion productivity and auality improve the reliability of component inserting,increase work efficiency,save labor cost, and improve the competitive-ness of customers.

2. Visual auto positioning PCB coordinates

3. The front end of the camera identification positioning pin realizes automatic compensation of pin offset, and the distortion of the pin exceeds the set value automatically to dump components,so as to ensure the accuracy of insertion.

4. It has a optional function to change component pin shape for reducing dumping rate.

5. The frameis made of castiron,and after along time aging treatment,to ensure the life of the equipment and ensure stable accuracy.

6. The head adopts a hanging design, and the whole machine adopts two-sided feeding, which greatly saves space.

1. Two vacuum pneumatic clamping jaw

Two vacuum pneumatic clamping jaw can be 360° rotated and insert. Inserting Angle is not limited. With a unique head design,it can pick up components simultaneously and save pick-up time.

2. Four vacuum pneumatic clamping jaw

Four vacuum pneumatic clamping jaw can be 360° rotated and insert.Inserting Angle is not limited. With aunique head design,it can pick up components simultaneously and save pick-up time.

3. Eight vacuum pneumatic clamping jaw

Eight vacuum pneumatic clamping jaw can be 360 rotated and insert.Inserting Angle is not limited. With a unique head design,it can pick up components simultaneously and save pick-up time.

Technical Parameters:

| Items | E200 | E410 | E800 |

| Insertion speed | 0.6S/PCS (Gripper) | 0.5S/1S PCS(Gripper) | 0.55S/PCS (Gripper) |

| 0.6S/PCS (Vacuum) | 0.5S/0.9S PCS (Vacuum) | 0.55S/PCS (Vacuum) | |

| Insertion accuracy | ± 0.03mm | ± 0.03mm | ± 0.03mm |

| Component size | 3mm-40mm | 3mm-40mm | 3mm-40mm |

| Component height | 30mm | 35mm/55mm (option) | 35mm/55mm (option) |

| Gripper changeable | option | option | option |

| Insertion direction | 0-360° | 0-360° | 0-360° |

| PCB size | Max 50mm*350mm | Max 50mm*350mm | Max 50mm*350mm |

| PCB Thickness | 0.8-5.0mm | 0.8-5.0mm | 0.8-5.0mm |

| PCB weight | Max 5kg | Max 5kg | Max 5kg |

| Rail height | 900mm±20 | 900mm±20 | 900mm ±20 |

| Insertion component | Connector, outlet port, switch button, capacitor, transformer, chip | Connector, outlet port, switch button, capacitor, transformer, chip | outlet port, switch button, capacitor, transformer, chip |

| Feeder type | Bulk, Tape, Tube, Tray and Auto-Tray Feeder | Bulk, Tape, Tube, Tray and Auto-Tray Feeder | Bulk, Tape, Tube, Tray and Auto-Tray Feeder |

| Insertion number | 2 | 4 | 8 |

| Machine dimension (L*W*H) | 1400*1600mm,1660mm | 1400,1500mm*1600mm | 1400*1600mm*1600mm |

| Machine weight | 1600KG | 1600KG/1500KG | 1500KG |

| Power supply | 220VAC (single phase) 50HZ | 220VAC (single phase) 50HZ | 220VAC (single phase) 50HZ |

| Apparent power | 4KVA | 4KVA | 4KVA |

| Operation air pressure | 0.5±0.05MPa | 0.5±0.05MPa | 0.5±0.05MPa |

| Airconsumption | 30 l/min | 70 60 l/min | 70 l/min |

| Operation temperature | 5-30°C | 5-30°C | 5-30°C |

| Machine noise | 70dB | 70dB | 70dB |

| Upload file format | TXT | TXT | TXT |

| Tape feeder | Stick Feeder | Auto-tray Feeder | Bowl Feeder | ||

| Radial | Axial | ||||

| E410 | 10 | 5 | 10 | 1 | 4 |

| E800 | 20 | 10 | 20 | 2 | 8 |

| E200 | 4 | 2 | 2 | 1 | 4 |